Executives See Growing Supply Chain Risks, Costlier Disruptions

Source:Deloitte Development LLC

A recent survey from Deloitte shows that global executives are increasingly concerned about the growing risks to their supply chains and costly negative impacts, such as margin erosion and inability to keep up with demand. Of the 600 executives surveyed, 38% held C-suite titles. Respondents represented large and small companies in a variety of industries and from countries around the globe, with the majority located in North America, Europe and China. The responses are detailed in a report, The Ripple Effect: How manufacturing and retail executives view the growing challenge of supply chain risk.

As organizations operate in an environment of escalating risk, an alarming 45% of the surveyed executives say their supply chain risk management programs are only somewhat effective or not effective at all. Meanwhile, executives surveyed recognize the strategic importance of supply chain risk, with 71% responding that supply chain risk is an important factor in their strategic decision-making.

“Supply chains are increasingly complex and their interlinked, global nature makes them vulnerable to a range of risks,” says Kelly Marchese, principal, Deloitte Consulting LLP, who specializes in manufacturing operations and supply chain strategy. “This increased complexity, coupled with a greater frequency of disruptive events such as geopolitical events and natural disasters, presents a precarious situation for companies without solid risk management programs in place.”

As indicated by survey responses, supply chain disruptions appear to be not only more frequent, but are also having a larger negative impact. Macro trends such as globalization and global connectivity are making supply chains more complex and amplifying the impact of any problems that may arise. Trends such as lean manufacturing, just-in-time inventory, reduced product lifecycles, outsourcing and supplier consolidation have yielded compelling business benefits, but they have also introduced new kinds of supply chain risk and reduced the margin for error.

Following are some of the major themes from the survey:

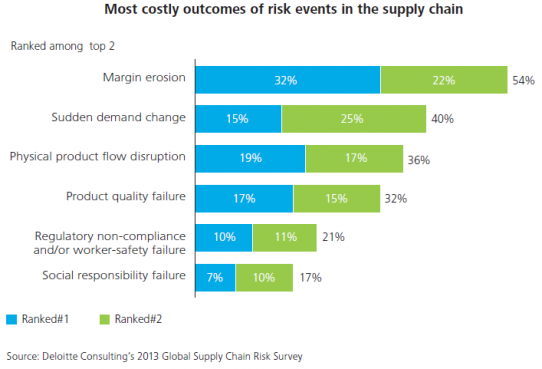

Margin erosion and “sudden demand changes” cause some of the most significant impacts. More than half (53%) of executives surveyed said that supply chain disruptions have become more costly over the last three years. Executives from the technology, industrial products and diversified manufacturing sectors were most likely to report that supply chain disruptions have become more costly. Some of the most common and most costly outcomes of supply chain disruptions are erosion of margins and an inability to keep up with sudden changes in demand, illustrating the extent to which the supply chain risk issue affects the “heart of the business.” Consumer products, diversified manufacturing and energy companies especially were likely to report margin erosion as one of their most costly issues.

Forty percent of respondents cited “sudden demand changes” as one of their two most costly problems—a reflection of ongoing challenges involved with growing customer expectations, short product cycles and emerging competitive challenges. Executives at retail and technology companies, which operate in a world where markets change rapidly, were most likely to identify demand change as being costly.

Most concern is about extended value chain. By and large, executives surveyed are more concerned about risks to their extended value chain—outside suppliers, distributors and customers—than about risks to company-owned operations and supporting functions. Problems with collaboration, lack of end-to-end visibility and the need to justify investment in supply chain risk programs add to the difficulty in managing the extended value chain.

Supply chain risk management is not always considered effective. Nearly two-thirds of the companies represented by the respondents have a supply chain risk management program in place, but only half the surveyed executives believed those programs are extremely or very effective. The top two challenges according to executives surveyed were “lack of acceptable cross-functional collaboration” (32%), followed by “cost of implementing risk management strategies” (26%). There are also organizational factors making effective supply chain risk more difficult: Three-quarters (75%) of executives said their supply chain risk management model is organized around silos, which can lead to a lack of supply chain visibility and collaboration and make it difficult to assess and manage risk on a holistic basis.

Many companies lack the latest tools. Current tools and limited adoption of advanced technologies are often constraining companies’ ability to understand and mitigate today’s evolving supply chain risks. Although many of the surveyed executives report using a wide range of tools to manage risk, only 36% use predictive modeling and less than one-third (29%) use risk sensing data, worst case scenario modeling, or business simulation—tools that can help drive more proactive management of supply chain risk.

“Many companies have some form of a supply chain risk management program, but unfortunately they do not always get the results they need from these programs,” says Ms. Marchese. “To be effective, companies should take a holistic and integrated approach to managing supply chain risk and go beyond traditional approaches.” She cites four important attributes that can be critical to supply chain resilience:

Visibility: The ability to monitor supply chain events and patterns as they happen, which enables companies to proactively—and even preemptively—address problems.

Flexibility: Being able to adapt to problems efficiently, without significantly increasing operational costs and make timely adjustments that limit the impact of disruptions.

Collaboration: Having trust-based relationships that allow companies to work closely with supply chain partners to identify risk and avoid disruptions.

Control: Having policies, monitoring capabilities and control mechanisms that help confirm that procedures and processes are actually followed.

With today’s complex, global supply chains, risk cannot be eliminated. Having the ability to promptly bounce back from problems and continue business operations as efficiently as possible can be integral to staying competitive. Because of the complex nature of today’s supply chains, disruptions will likely occur. “True resilience,” notes Ms. Marchese, “means building in the ability to recover efficiently and decrease the impact of those events.”

- Login to post comments